The Key Benefits of Using Membrane Switches in Manufacturing

Checking Out the Conveniences of Membrane Switches Over for Modern Electronics

The exploration of membrane buttons in contemporary electronic devices provides a remarkable point of view on their myriad advantages, specifically in terms of style flexibility, longevity, and cost-effectiveness. As markets proceed to progress, the function of membrane switches in enhancing user experience and operational effectiveness warrants better exam.

Benefits of Membrane Layer Buttons

Membrane layer switches are increasingly favored in modern electronics as a result of their various advantages. Among the key benefits is their small design, which permits space-efficient assimilation into various tools. This slim profile not only conserves space yet likewise adds to the general aesthetic allure of electronic items.

Another advantage is their resilience. Membrane layer switches are commonly immune to moisture, dirt, and impurities, making them excellent for use in environments where direct exposure to severe conditions is a worry. This resistance expands the life expectancy of the buttons, decreasing the demand for frequent substitutes and upkeep.

Additionally, membrane switches offer exceptional responsive feedback, enhancing user experience. The tactile action is usually designed to provide a gratifying sensation upon activation, which can enhance individual fulfillment and efficiency.

Additionally, the production process of membrane layer buttons is economical, permitting lower production prices compared to traditional mechanical switches. This affordability makes them suitable for a large range of applications, from customer electronics to commercial machinery.

Design Versatility and Modification

The layout flexibility and modification options offered by membrane switches over additionally improve their charm in contemporary electronics. These switches can be tailored to fulfill certain visual and useful demands, enabling manufacturers to create tools that align very closely with brand name identification and customer choices. With numerous alternatives in regards to shades, shapes, and dimensions, membrane layer buttons can perfectly incorporate into varied item layouts, whether for customer electronics, commercial applications, or clinical devices.

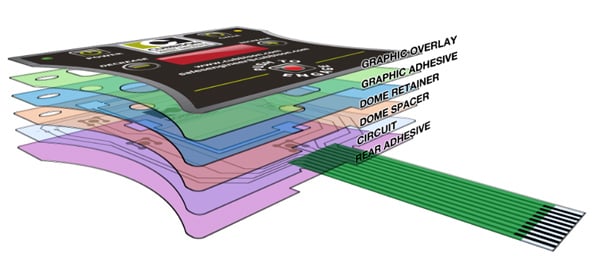

Furthermore, the ability to include graphics and signs straight onto the button surface area boosts usability while reducing the need for additional labeling. This integration not just simplifies manufacturing processes but additionally contributes to a sleeker general look. The design can be further tailored with attributes such as backlighting, responsive feedback, and multi-layer buildings, offering boosted user communication.

Resilience and Environmental Resistance

Furthermore, membrane buttons can be engineered to be chemically resistant, making them ideal for applications in commercial settings where exposure to solvents and cleansing agents is common. The encapsulation of digital components within the membrane structure offers additional defense against environmental tensions, guaranteeing reliable performance also in tough conditions.

Along with physical sturdiness, membrane switches over exhibit superb resistance to UV light, avoiding destruction and discoloration with time (membrane switch). This characteristic is particularly valuable for outdoor applications, where prolonged direct exposure to sunshine can jeopardize various other switch types

Ultimately, the sturdiness and environmental resistance of membrane layer switches make them a perfect choice for a wide variety of modern digital devices, from clinical tools to customer electronic devices, guaranteeing regular capability and user fulfillment throughout various applications.

Cost-Effectiveness in Production

Cost-effectiveness in manufacturing is a substantial benefit of membrane layer buttons, making them a recommended option for producers in different industries. The manufacturing process of membrane switches typically includes less materials contrasted to conventional buttons, which lowers basic material prices. This streamlined production process not important site just conserves cash yet likewise reduces waste, aligning with modern sustainability goals.

Furthermore, membrane switches can be created making use of automated methods, enabling high-volume result with decreased labor prices. The combination of advanced printing innovations better improves performance, making it possible for makers to achieve intricate layouts and performances without sustaining substantial added costs. This scalability guarantees that production can adapt to transforming market needs without compromising quality or enhancing expenses.

Furthermore, the light-weight nature of membrane changes adds to set you back financial savings in delivery and handling, as well as in the overall style of digital devices. By getting rid of large parts, manufacturers can enhance the total product design, thereby improving market competitiveness. On the whole, the cost-effectiveness of membrane layer switches not only benefits makers economically but also promotes advancement and quick item development in the vibrant landscape of contemporary electronics.

Applications in Various Industries

Convenience sticks out as a hallmark of membrane switches, allowing them to locate applications throughout a vast array of sectors. In the health care field, these buttons are important to clinical devices, supplying easy to use user interfaces for devices like infusion pumps and diagnostic equipments. Their resistance to moisture and very easy cleaning make them ideal for settings calling for strict go to this website hygiene standards.

In the vehicle industry, membrane buttons add to the capability of dashboards and control board, supplying a sleek, modern look while ensuring sturdiness against extreme conditions. Their light-weight style also supports general lorry efficiency.

Moreover, commercial equipment employs membrane switches for operational controls. Their robust nature and customizable features deal with the specific requirements of varied applications.

Conclusion

In final thought, membrane switches deal substantial benefits for modern-day electronics, including layout versatility, sturdiness, and cost-effectiveness. membrane switch. Their personalized functions and resistance to environmental aspects make them suitable for a variety of applications throughout numerous industries. As technological demands remain to develop, the convenience and efficiency of membrane switches over placement them as a vital component in improving customer experience and driving development within the competitive landscape of electronic tools